Forge Black Front Mount Intercooler Kit Hyundai Veloster N 2019-2021 Forge Motorsports

$ 940,80 $ 235,20

Part #: FMINT22

Utilizing our industry leading bar and plate design, alongside Solidworks CAD and flow simulation design (Computational Fluid Dynamics CFD) we developed our high flow cast end tanks. The turbo side end tanks feature an internal divider to ensure the full volume of the stepped core is utilized.

The bar and plate core has over 129% more volume and an increase of frontal surface area over 71% (over the stock cooler) meaning the Forge intercooler is the largest currently available on the market. To ensure we deliver optimum cooling efficiency, the development team created a fabricated ducting system that has been skillfully integrated into the superior design of this product this ensures fitment to the inner contour of the Veloster N front bumper.

The inlet and outlet sizes have been increased in diameter to 65mm, giving an increase of 27% more volume over the stock cooler to give perfect flow. The development team also added a custom hard pipe increasing the diameter by 14 mm to 64mm up from the factory 50mm. This replaces the stock factory pipe on the hot side to ensure this package gives you all you need for maximum performance gains on high levels of tune. The boost pipe and intercooler come in our standard black textured finish powder coat for maximum longevity.

Various core designs where tested in the development of the Veloster N intercooler with us finally deciding to use a high-quality Bar and Plate design as used on our highly successful Audi RS3 and TTRS 8s intercoolers resulting in minimal pressure drop.

The results were fantastic with IATS (inlet air temps) being reduced by half and resulting in tremendous gains on tuned vehicles.

During our extensive testing, we let the car heat soak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of around 40°C). We then did a dyno pull from this point. By doing this, it gives a more consistent result and reflects real-world driving conditions more accurately. You can easily see the Forge intercooler cools much quicker and delivers a much greater drop in temperature compared to OEM.

After more than six pulls on the dyno we still had super safe IATs and the Forge intercooler gave results of 24°C, halving the factory’s intercooler intake temps from 48°C. These tests took place in relatively cold conditions with an ambient dyno cell temperature of 15°C proving how inefficient the stock intercooler is. In the summer months the stock intercooler along with higher inlet air temperatures will have a hugely negative impact on the engine’s performance. In these conditions the engine management will retard the ignition, resulting in a lower powered engine as temperatures rise and the ECU then pulls out the timing to stop detonation. On a mapped vehicle the results will be even more detrimental and can lead to possible premature engine wear.

This intercooler combined with our intake, and a quality aftermarket cat back exhaust will deliver you unparalleled levels of performance, the final testing results were very notable; not only did the Forge intercooler halve the IATS but significantly increased both power and torque over Hyundai’s claimed figures of 275bhp and 278lb/ft of torque to an impressive 307bhp and 347lb/ft of torque.

Prompt Delivery and Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other leading international carriers, we are able to provide various shipping options. Our warehouse personnel are well trained and will be able to pack your goods in accordance with the exact and precise specifications. Your goods will undergo an exhaustive examination before they will be properly packaged prior to being shipped. We deliver to thousands of customers every day from all over the world. The fact that we are dedicated to becoming the largest online retailer in the World is clear. These warehouses are situated in Europe just as they are in the USA.

Note: Orders that contain more than one product are assigned a specific processing time depending on the specific product.

We will inspect each and every one of the items ordered before shipping. Most orders are delivered within 48 hours. The delivery time will be between 3-7 working days.

Returns

Stock is dynamic, and not fully managed by us due to the involvement of multiple different parties, such as the factory and our warehouse. Actual stock levels may fluctuate at any time. Be aware that your order may be out of stock once the order is placed.

Our policy is valid for 30 days. We cannot exchange or refund your order if it has been 30 days from the date of purchase.

The item must not be used and in its original condition. It must also be returned in its original packaging.

Related products

Exterior Fenders

Exterior Fenders

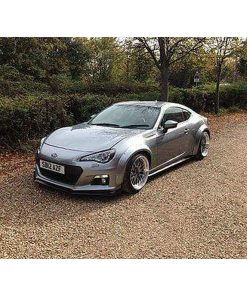

ABW Motorsport Fender Flares Set Subaru BRZ 2013-2016 ABW Motorsport

Exterior Fenders

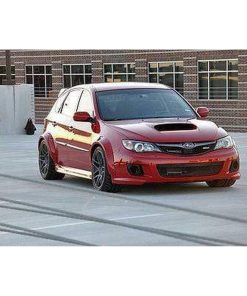

ABW Motorsport 80mm Recessed Arch Fender Flares Subaru WRX / STI 2002-2005 Sedan ABW Motorsport

Exterior Fenders

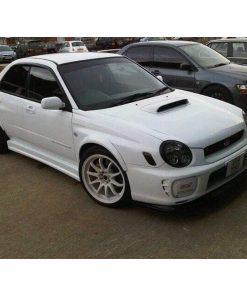

ABW Motorsport Rear Wide Fender Arch Kit Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Exterior Fenders

Engine Power Packages

Exterior Spoilers and Wings

ABW Motorsport Ducktail Spoiler Subaru WRX / STI 2002-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

Interior Floor Mats

Interior Floor Mats

3D Maxpider Heavy Duty All Weather Floor Mats Subaru BRZ 2013-2020 3D MAXpider

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed Two Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport Fender Flares Arch One Piece Bond-On Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport

Exhaust Axle Back

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Interior Floor Mats

Interior Floor Mats

3D Maxpider 2022-2024 Subaru WRX Floormats | L1SB03601509 3D MAXpider

Engine Power Packages

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport