King Engine Rod Bearings 52mm Journal Size Subaru WRX / STI EJ20/EJ22/EJ25 2002-2021 King Engine Bearings

$ 41,01 $ 24,61

Your high performance engine build deserves the most advanced internal components designed to withstand the highest loads and RPMs. So what makes King Engine Bearings track tough and street smart? All King bearings are designed with the closest wall tolerances in the industry, with all shells matched to 0.0001″. Greater rod bearing height improves bearing-to-bore contact and heat transfer, greatly reducing spin potential at high RPMs. Utilizing enlarged and chamfered oil holes for equal distribution under heavy load, King bearings are built tough enough for even the highest temperatures at the fastest engine speeds. Versatility is the name of the game which is why King offers the industry’s widest selection of sizing including special clearance options for advanced custom builds.

XP Bearings: XP bearings are designed for dedicated track applications or street cars that may see extended circle track racing or endurance events. Formed from enhanced tri-metal copper lead construction, XP bearings utilize a nickel barrier fused with a SecureBond adhesion process. XP bearings feature a 15%-30% greater load capacity than traditional bearings and 0.0005″ metallurgical enhanced and hardened performance overlay for extended fatigue resistance. XP main bearings are 1/2 grooved for un-compromised lower shell load capacity.

Please Note When Ordering Bearings:

- Engine bearings require proper tolerance to be measured before purchase. If you are not sure what size bearings your build requires, please consult a professional engine builder. We are not responsible for incorrectly ordered bearings and can not take returns or provide exchanges on any engine internal components.

Size: (Suites 52mm Journal Size)

| Size | Standard, Standard w/ Extra Oil Clearance, 0.25 Oversized, .026 Oversized, 0.5 Oversized |

|---|

Prompt Delivery and Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other leading international carriers, we are able to provide various shipping options. Our warehouse personnel are well trained and will be able to pack your goods in accordance with the exact and precise specifications. Your goods will undergo an exhaustive examination before they will be properly packaged prior to being shipped. We deliver to thousands of customers every day from all over the world. The fact that we are dedicated to becoming the largest online retailer in the World is clear. These warehouses are situated in Europe just as they are in the USA.

Note: Orders that contain more than one product are assigned a specific processing time depending on the specific product.

We will inspect each and every one of the items ordered before shipping. Most orders are delivered within 48 hours. The delivery time will be between 3-7 working days.

Returns

Stock is dynamic, and not fully managed by us due to the involvement of multiple different parties, such as the factory and our warehouse. Actual stock levels may fluctuate at any time. Be aware that your order may be out of stock once the order is placed.

Our policy is valid for 30 days. We cannot exchange or refund your order if it has been 30 days from the date of purchase.

The item must not be used and in its original condition. It must also be returned in its original packaging.

Related products

Interior Floor Mats

3D MAXpider Subaru WRX / STI 2015-2021 Kagu Black Cross Fold Cargo Liner 3D Maxpider

Exterior Fenders

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX / STI 2004-2005 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport Fender Flares Arch One Piece Bond-On Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport Fender Flares Set Subaru BRZ 2013-2016 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exhaust Axle Back

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Engine Power Packages

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport

Engine Power Packages

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX / STI 2004-2005 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Front and Rear Arch Fender Flares Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch Bolt-On One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

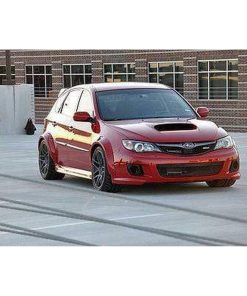

Engine Power Packages

300WHP Power Pack 2022-2024 Subaru WRX 6MT/CVT (USDM Only) Import Image Racing

Exterior Body Kit

ABW Motorsport 4 Door to 2 Door Conversion Rear Quarters Subaru WRX / STI 2002-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Interior Floor Mats

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport