ARP Head Studs Mitsubishi EVO X 2008-2015 ARP

$ 188,66 $ 75,46

Part #: 207-4206

Obtaining the optimum cylinder head-to-block sealing is especially critical in small displacement engines employing high compression pistons or power adders like turbochargers, nitrous oxide and superchargers. That’s why ARP« head studs are popular among leading Sport Compact/Import racers.

You should know that ARP« uses a premium grade 8740 alloy that is rated far superior to “aircraft” quality. Then, each stud is precisely heat-treated to 200,000 psi. Following heattreat, each stud is centerless ground to make it as close to perfectly concentric as possible. This procedure involves about ten very slight cuts and results in an exceptionally straight part. It’s important to note that lesser quality studs are not even centerless ground_the material is thread rolled in bar stock form (mostly before heat-treat, when the material is easier to machine). Because ARP« studs are manufactured to such exacting tolerances, you will note that gaskets and cylinder heads literally glide into position and are perfectly aligned_something that won’t happen with inferior quality head studs.

ARP« studs are thread rolled after heat-treat, which gives them about 1000% (that’s ten times) better fatigue strength than those studs that are threaded prior to heat-treat.

Part #: 207-4206

Professional packing and fast shipping

We can offer a variety of shipping options because of our long-term relationship with UPS FedEx DHL. Our warehouse personnel is highly-skilled and will wrap your goods in accordance with our exact and accurate specifications. Your items will undergo a thorough inspection and be adequately secured before being delivered. We deliver to hundreds of thousands of customers daily across various countries. This shows our commitment to being the largest online retailer in the world. The warehouses and centers of distribution are situated in Europe and the USA.

Note that orders containing multiple items are processed according to the item.

Prior to shipment, we will examine thoroughly the items you've purchased. The majority of orders are shipped within 48 hrs. Delivery is expected to take between 3 and 7 days.

Returns

We are not able to control the inventory in our warehouse or factory. Actual stock levels may fluctuate at any point. It's possible that your order will be unable to fill when you have placed the order.

Our policy lasts for thirty days. If it's been more 30 days since the date you made your purchase and we're unable to offer you a complete refund or exchange.

To be eligible for a refund, your product must be unopened and in the same state as you received it. You must have the item in the original packaging.

Related products

Engine Power Packages

Exterior Fenders

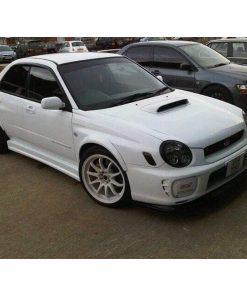

ABW Motorsport 40mm Fender Flares Arch Bolt-On One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Interior Floor Mats

Exterior Front Lips

ABW Motorsport Front Lip Subaru WRX / STI 2006-2007 ABW Motorsport

Exterior Fenders

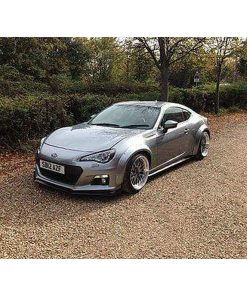

ABW Motorsport Fender Flares Set Subaru BRZ 2013-2016 ABW Motorsport

Exterior Fenders

Exterior Spoilers and Wings

ABW Motorsport Ducktail Spoiler Subaru WRX / STI 2002-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport 80mm Recessed Arch Fender Flares Subaru WRX / STI 2002-2005 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed Two Piece Subaru WRX / STI 2004-2005 Sedan ABW Motorsport

Exterior Body Kit

ABW Motorsport 4 Door to 2 Door Conversion Kit Subaru WRX / STI 2002-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport Rear Wide Fender Arch Kit Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Engine Power Packages

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Interior Floor Mats

3D Maxpider 2022-2024 Subaru WRX Floormats | L1SB03601509 3D MAXpider

Exterior Fenders

ABW Motorsport Fender Flares Arch One Piece Bond-On Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Interior Floor Mats

3D Maxpider Heavy Duty All Weather Floor Mats Subaru BRZ 2013-2020 3D MAXpider

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Front and Rear Arch Fender Flares Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport