Manley Connecting Rods 93-99 Eclipse / 2003-2006 Evolution (7 Bolt ONLY) Manley Performance

$ 518,00 $ 155,40

Manley has been in business since 1966 producing aftermarket and OEM engine internals, supplying such cars as the Ford GT. Manley’s premier connecting rod series is the Turbo Tuff line which was designed to be the best money can buy. Manley Performance is synonymous with winning and their products power some of the fastest cars around.

Manley H-Beam rods are a lower cost alternative to the Turbo Tuff series, they are partially produced in China and then finished in the US to reduce costs but retain quality. These rods are an excellent alternative to Eagle rods, both of which should be considered when buying either one. Manley H Beam rods are weight matched within +/- 1.5 grams of each other and both ends of the rod are rounded perfectly. These are the perfect rods for street applications pushing up to 600 wheel horsepower.

Manley Turbo Tuff I Beam Rods are made using forged 4340 aircraft quality vacuum degassed material. Manley Turbo Tuff rods are machined in house, in the USA, to ensure the highest quality product. Each rod is shot-peened after machining and magnafluxed. The bores are round with no taper and these rods use APR 2000 cap screws for ultimate strength.

Pro series rods are the strongest rod Manley offers and are also made of 4340 aircraft quality material. They are fully machined to produce the lightest rod with the most holding power possible. These rods are designed to be used with cars making 1300+ horsepower. They are shot peened and 100% magnafluxed and use either 3/8in ARP 2000 fasteners or optional super strength ARP Custom Age 625+ cap fasteners.

Note:

Manley rods are sold in sets of four.

Be sure you know wether you have a 6 bolt or a 7 bolt 4G63 before ordering.

Specs:

- Center-to-Center

- Big End Bore

- Big End Width

- Pin Diameter

- Pin Bore

- Gram Weight

| Style | H-Beam Rods, Pro Series Alloy Rods with Standard Fasteners, Pro Series Alloy Rods with Upgraded Fasteners, Turbo Tuff I Beam Rods (+12mm Longer), Turbo Tuff I Beam Rods (+6mm Longer), Turbo Tuff I Beam Rods (Lightweight Straight Beam Design), Turbo Tuff I Beam Rods (Stock Size) |

|---|

Prompt Delivery and Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other leading international carriers, we are able to provide various shipping options. Our warehouse personnel are well trained and will be able to pack your goods in accordance with the exact and precise specifications. Your goods will undergo an exhaustive examination before they will be properly packaged prior to being shipped. We deliver to thousands of customers every day from all over the world. The fact that we are dedicated to becoming the largest online retailer in the World is clear. These warehouses are situated in Europe just as they are in the USA.

Note: Orders that contain more than one product are assigned a specific processing time depending on the specific product.

We will inspect each and every one of the items ordered before shipping. Most orders are delivered within 48 hours. The delivery time will be between 3-7 working days.

Returns

Stock is dynamic, and not fully managed by us due to the involvement of multiple different parties, such as the factory and our warehouse. Actual stock levels may fluctuate at any time. Be aware that your order may be out of stock once the order is placed.

Our policy is valid for 30 days. We cannot exchange or refund your order if it has been 30 days from the date of purchase.

The item must not be used and in its original condition. It must also be returned in its original packaging.

Related products

Engine Power Packages

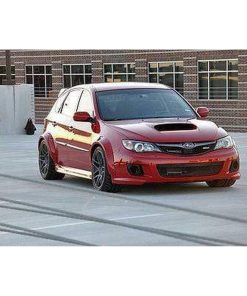

Exterior Fenders

ABW Motorsport 40mm Fender Flares Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Front Lips

ABW Motorsport Front Lip Subaru WRX / STI 2006-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport Rear Wide Fender Arch Kit Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Interior Floor Mats

Engine Power Packages

300WHP Power Pack 2022-2024 Subaru WRX 6MT/CVT (USDM Only) Import Image Racing

Exterior Fenders

ABW Motorsport 40mm Fender Flares Recessed Two Piece Subaru WRX / STI 2004-2005 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed Two Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX / STI Sedan 2004-2005 ABW Motorsport

Interior Floor Mats

3D Maxpider 2022-2024 Subaru WRX Floormats | L1SB03601509 3D MAXpider

Interior Floor Mats

3D Maxpider Heavy Duty All Weather Floor Mats Subaru BRZ 2013-2020 3D MAXpider

Exterior Fenders

ABW Motorsport 40mm Fender Flares Arch Bolt-On One Piece Subaru WRX 2002-2003 Sedan ABW Motorsport

Interior Floor Mats

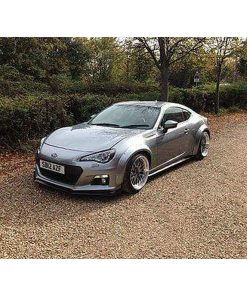

Exterior Fenders

ABW Motorsport Fender Flares Set Subaru BRZ 2013-2016 ABW Motorsport

Exterior Fenders

ABW Motorsport Fender Flares Arch One Piece Bond-On Subaru WRX / STI 2002-2007 Sedan ABW Motorsport

Exterior Body Kit

ABW Motorsport 4 Door to 2 Door Conversion Rear Quarters Subaru WRX / STI 2002-2007 ABW Motorsport

Exterior Fenders

ABW Motorsport 80mm Recessed Arch Fender Flares Subaru WRX / STI 2002-2005 Sedan ABW Motorsport

Exterior Fenders

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX / STI 2006-2007 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Arch Two Piece Subaru WRX / STI 2004-2005 Sedan ABW Motorsport

Exterior Fenders

ABW Motorsport 60mm Fender Flares Recessed One Piece Subaru WRX Sedan 2002-2003 ABW Motorsport

Engine Power Packages